A complex and far-reaching communication system is an integral part of any modern city. Hundreds of kilometers of industrial and household pipelines, telephone and television cables form a vast infrastructure that is growing by leaps and bounds. Replacing the ones out of order and laying some new sections of communication networks in restricted urban conditions with the help of conventional (open) method is becoming more and more complicated, even impossible. While the communication network status is about to be critical and if any emergencies on water-carrying pipelines resulted in flooding urban territories, subsidence of buildings and structures, dilapidation of industrial pipelines would culminate in a global disaster. Subsoil waters and soil cannot be decontaminated.

Kombest’s line of activities encompasses development and improvement of operation diagrams, design and serial production of equipment sets for replacing and laying pipelines trenchlessly. The technologies and equipment sets are under protection of RF and international patents. The paper called Replacing Sewerage in Urban Conditions without Excavation was awarded the Prize of the Russian Government in 2000.

The technologies and equipment offered by Kombest Company:

- Sets for replacing cast-iron, ceramic, asbestos-cement, concrete and reinforced concrete (sewerage) pipelines with polyethylene ones (up to 630 mm in diameter);

- Sets for replacing steel and cast-iron (tap water) pipelines with polyethylene ones (up to 530 mm in diameter) trenchlessly;

- Sets for laying water-carrying polyethylene pipelines (up to 400 mm in diameter) trenchlessly;

- Sets for laying (plugging up) steel pipelines (up to 1,400 mm in diameter);

- Sets for burying end-bearing piles made of steel pipes (up to 600 mm in diameter); and

- Sets for moulding cast-in-place piles (up to 300 mm in diameter).

Besides, Kombest Company carries out a complex of works to revamp and lay utility lines of various purposes, mould cast-in-place piles and bury end-bearing piles through their own employees. The employees of Kombest carry out works on any faulty sections of pipelines in the shortest time possible ensuring high quality and giving a guarantee.

Application

Trenchless communication replacement

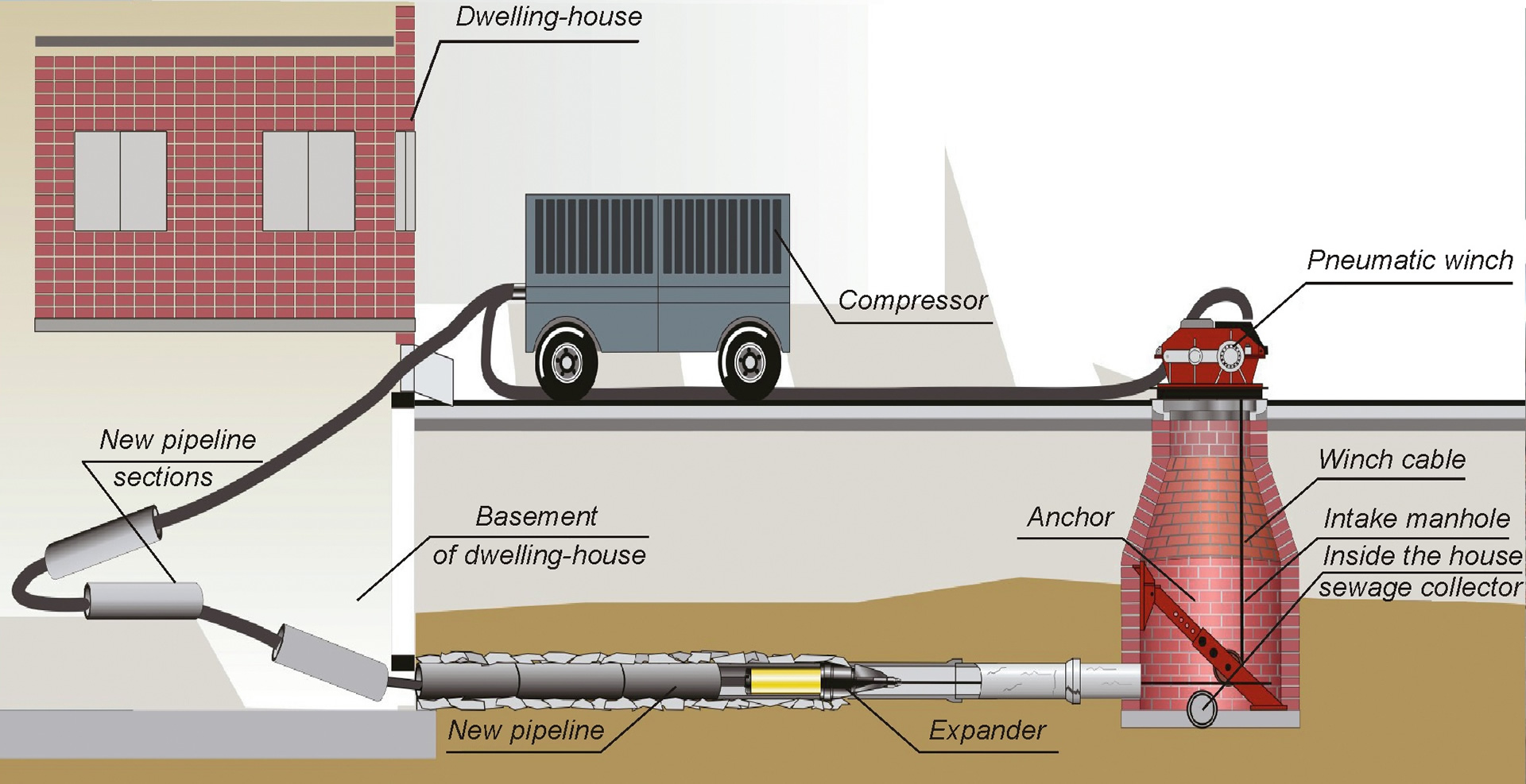

Old pipes are trenchelessly replaced with new ones during revamp or top-to-bottom renovation of the existing subsoil communications in any urban environment and industrial facilities. The technology developed enables us replace steel, cast-iron and non-metal pipelines from 100 to 350 mm in diameter with plastic pipes ranging between 160 and 400 mm trenchlessly. The essence of the technology is that a special enlarging head is mounted on the percussion device located in an entrance well. An air-bearing hose and a hoisting gear able passing through the pipeline section being replaced are connected to the machine. While the device is moving along the pipeline being replaced, the enlarging head is breaking it, pressing chips into the soil and dragging the new pipeline into the formed tunnel. The new pipeline is advanced section by section in the entrance well.

The equipment used:

- Pneumopercussion device of the required diameter;

- Enlarging head;

- Anchor device;

- Pneumatic hoisting gear with the tractive force of 3 tons or 5 tons;

- Device for connecting plastic pipes;

- Set of air-bearing hoses; and

- Set of tools and spare parts.

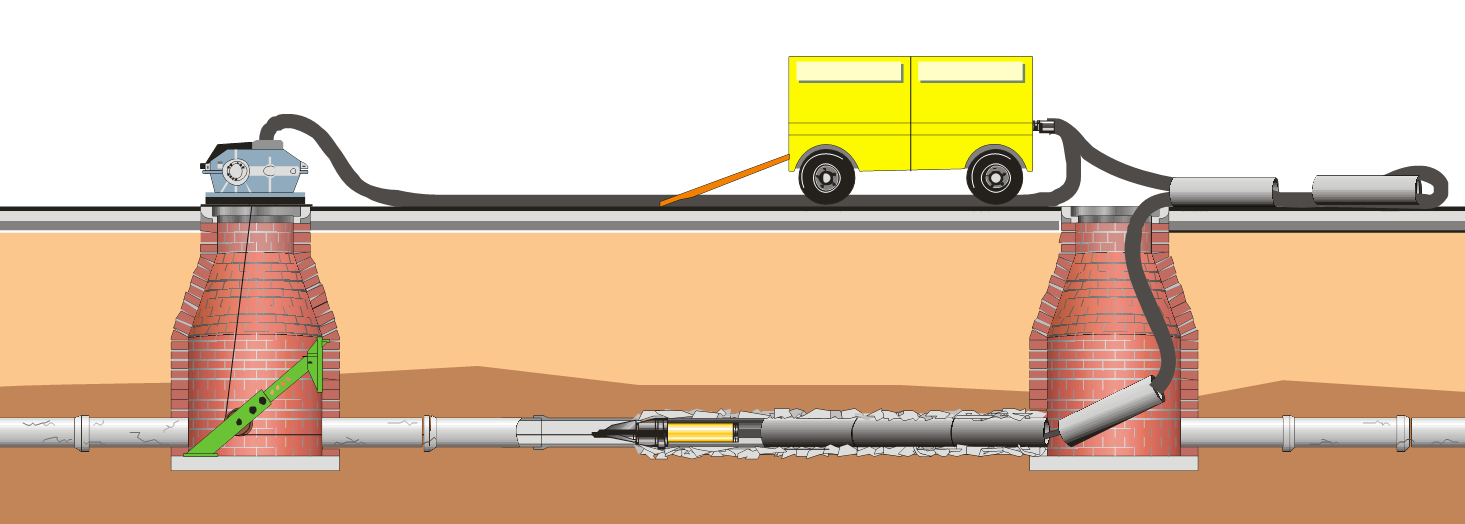

Diagram of trenchless replacement of faulty pipelines:

Operating principle of a pneumopercussion device:

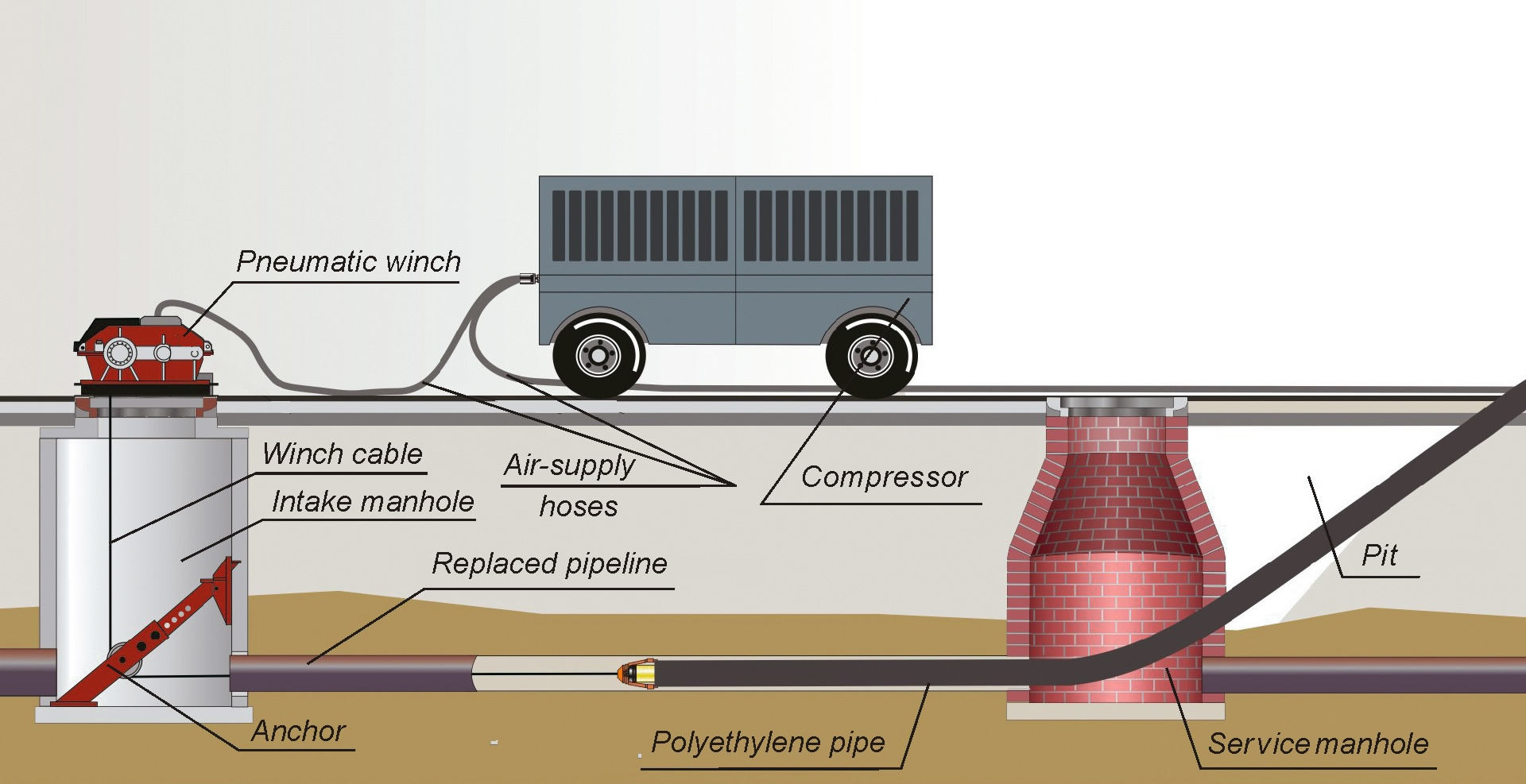

Trenchless replacement of water supply lines

When laying water supply lines, polyethylene pipe sections are welded on the ground to form the required length. Along the previously arranged slanting assembly well, the sections get into the pit and later into the enlarged tunnel. In order to arrange the assembly well, a special starting unit is required.

The technology and the equipment set are designed for trenchless routing of new sections of sewerage and water supply lines. First, a leading well is made to join the pits located in the place of wells-to-be. A hauling cable is placed along the well, one end of the cable is attached to the hoisting gear (set on the exit well), while another end is connected to the pneumohammer. On the front of the pneumohammer, there is an enlarging head with a device for fixing a new plastic pipeline to it. When compressed air is first fed onto the hoisting gear, and then onto the pneumohammer, the working organ starts transferring impact stress onto the soil mass and compacting it, by that widening the leading well. When placing sewerage into the newly formed well, the plastic pipeline is dragged into it. Separate sections are built one on another with the help of threaded connections in the entrance pit.

The equipment used:

- Pneumopercussion device of the required diameter;

- Enlarging head;

- Anchor device;

- Pneumatic hoisting gear with the tractive force of 3 tons or 5 tons;

- Device for connecting plastic pipes;

- Set of air-bearing hoses; and

- Set of tools and spare parts.