The technology allows using the trenchless method to replace steel and cast-iron water supply pipelines from 80to 530 mm in diameter with polyethylene ones. Sets of six sizes have been designed.

Operational principle:

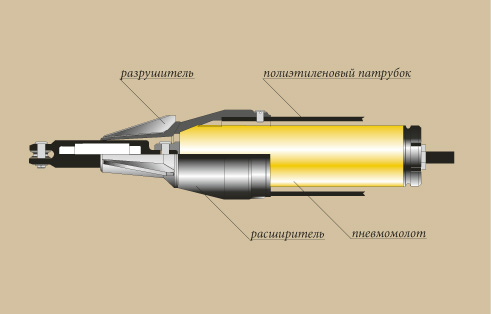

An enlarging head with ribs is mounted on the pneumohammer located in the work well, a preassembled length of a new pipeline is attached to this head. This length is dragged into the work well through the slanting well which is connected to the lower part of the work well. The hoisting cable passes through the replaceable section of the pipeline with the help of an anchor device located in the input well and joins the bow of the pneumohammer. During pneumohammer operation, the stroke is transmitted to the enlarging head and through it to the old pipe. The old pipe is destroyed and the soil is moved to the outer diameter of the enlarging head. The new pipe which is prewelded to form a certain length with the help of a pipe welding machine is dragged into the tunnel formed by the enlarging head movement. The pneumohammer design ensures its stable operation along 150 m section being laid, it is started up by tightening the hoisting cable. Waste energy is exhausted into the pipe being replaced.