The technology is used to create steel casing for a variety of utilities. The pipe diameter is up to 1,400 mm, length up to 80 mm. Set can also be used for vertical burying of metal end-bearing piles. Compacting soil masses and sheet pile walls are arranged by driving steel pipes into soil. The pipes are driven vertically or under the angle required. The diameter of steel pipes is between 150 and 600 mm, possible depth of buring is up to 10 m, cleaned or not.

Operational principle:

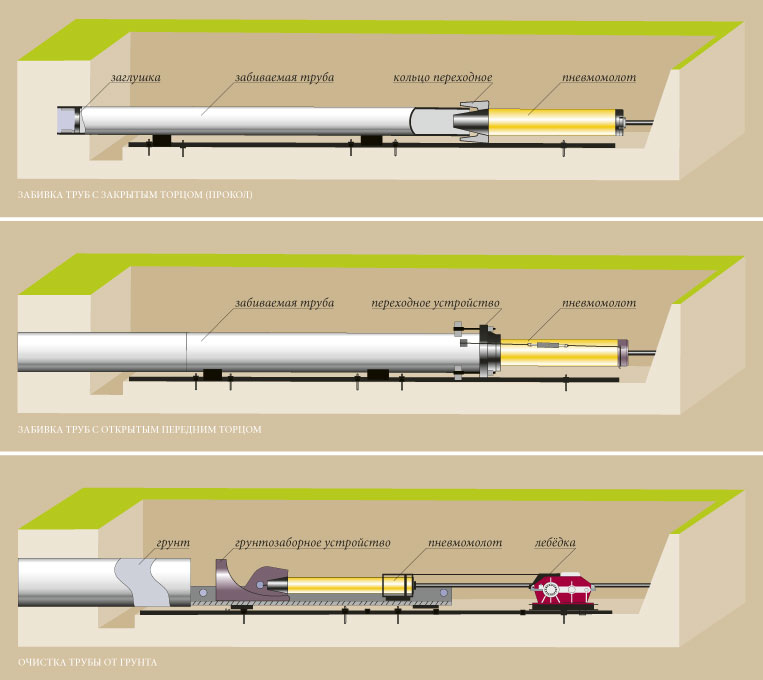

Pipes are driven into soil either with the closed front end (crack) or with the open one. Crack is possible in all the types of compacted soils. In order to improve precision of laying and speed of burying, depending on the soil type, varied heads of the driven pipe and special technological methods are used.

The technology of driving pipes with the open front end allows increasing a diameter of pipes laid thanks to frontal soil resistance if compared to the closed end. Piles are driven to their full length, and then are cleaned off the soil with self-propelling dredge head or are driven section by section while every section is cleaned.

Piping with closed butt end (crack): Plug; Dragged pipe; Transition ring; Pneumohammer; Piping with open butt end (crack); Dragged pipe; Transition ring; Pneumohammer; Pipe cleaning from soil; Soil; Dredge head; Pneumohammer; Hoisting gear.

SET CONTENTS: Pneumohammer for driving pipes; Pneumohammer of a dredge head; Adapter; Pneumatic hoisting gear; Dredge head (sampling pipe).