Laying of water-bearing pipelines

The technology allows trenchless method of laying a polyethylene pipe with diameters from 110 to 400 mm.

Principle of operation:

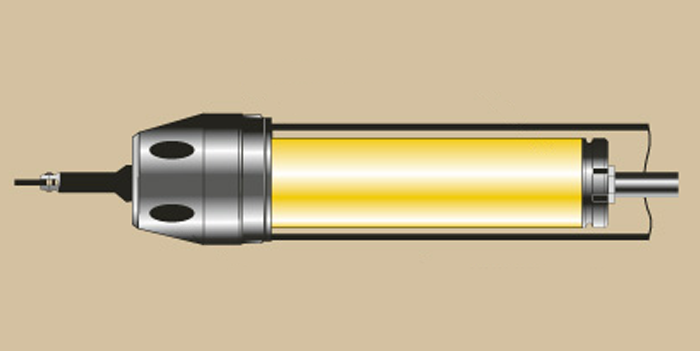

On the route of the pipeline being laid, intermediate installation wells are being constructed. Then a special pneumatic punch with a diameter of 70-90 mm passes the leading well. The cable from the winch is stretched to the leading well, the assembly wells are eliminated, an inclined well is laid in the working well, in which the impact unit with the expander is located.

When laying a pipeline with a diameter of more than 300 mm, the expander is provided with windows for partial passage of soil into the pipeline being laid. The laying process is carried out with the simultaneous operation of the winch and pneumatic hammer.